ARTICLE

With the continuing focus on building safety, fire-resistant cables – and their ability to service critical systems in the event of a fire – remain under the spotlight. Steve Williams, Commercial Manager for Wrexham Mineral Cables, talks about the differences between fire resistant cables, why the industry needs enhanced testing, and how the industry is tackling environmental issues.

What is a fire-resistant cable?

Fire resistant cables are designed to maintain circuit integrity and continue to work for a specified period of time under defined conditions. They play a fundamental role in ensuring that emergency and building critical systems are supported - including emergency lighting, sprinkler systems, extraction systems, smoke dampers and shutters, emergency generators, pressurisation fans, emergency voice comms and fire alarms - in the event of a fire, providing vital time for the safe passage of occupants out of the building, and allowing for shutdown procedures to take place.

What is the difference between MICC and polymeric fire-resistant cables?

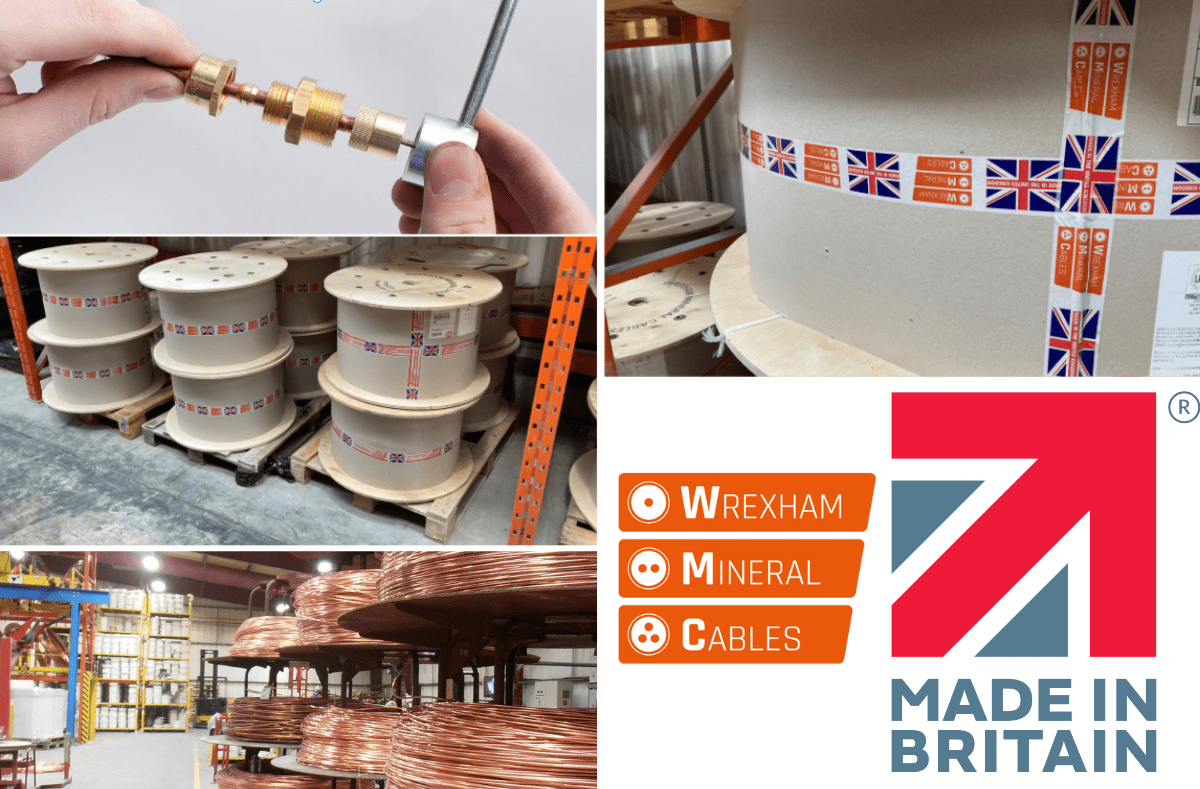

Mineral Insulated Copper Clad (MICC) Cable has been used commercially since the 1930s, and to this day is considered the only true fire survival cable.

It is made by placing magnesium oxide around copper rods inside a circular copper tube, known as the copper sheath, for its protection – meaning it has its own fire-proof conduit. And unlike any other type of fire-resistant cable, no polymers, tapes or armouring are used, so this type of cable will operate directly in the heart of a fire and continue to do so safely.

The continuous operating temperatures of cables are often a key factor in selection decisions. A bare mineral insulated cable can work continuously up to 250°C, far more than any other polymeric fire-resistant cable. Mineral Insulated Cables operate directly in the heart of a fire, continuing to function safely in temperatures in excess of 1,080°C for over three hours, whilst also undergoing direct impact and exposure to water pressure going above any current British Standard.

Its bespoke construction means it doesn’t require a conduit for mechanical or vermin protection and stops liquids and gas flowing through the cable. These extreme tolerances make it a perfect candidate to create water, air, and dust-tight seals with a fully approved mineral cable gland. Because of this, Mineral Insulated Cable is seen not just as a fire-resistant cable but the ultimate fire-survival cable, as it provides the best possible resistance to fire, heat, and impact damage. It is for this reason that this type of cable is trusted to operate under the most extreme and challenging conditions.

In comparison, polymeric fire-resistant cables rely on MICA tapes and polymers to increase their resistance to fire, yet these materials can burn away at as little as 80°C, exposing the critical conductors. And in order to give some soft skinned polymer cables flame-retardant properties, halogens are added to the outer sheath such as chlorine, bromine and fluorine. When exposed to a fire, these halogenated polymers release halides, which are extremely toxic. This smoke not only restricts breathing, but it also increases the risk of this being inhaled when following the common rules during a fire.

What current standards are there for fire resistant cables?

In order to meet the requirements of a fire-resistant cable, they must meet the British Standard appropriate to their type of fire-resistant cable. There are several references for fire performance on cables including BS 50200, BS8434, BS8519 and BS6387.

All of these standards have a variant of time and temperature the cables are tested at under fire conditions. These can range from a 30-minute rated cable tested at 830oC (PH30 cable as per BS 50200) to a three-hour rated cable tested at 940oC (BS 6387 category C). All of these standards should provide reassurance to the specifier that the chosen cable will continue to work in the event of a fire.

Wrexham Mineral Cables recently gained BS8519 CAT3 approval on the entire range of Heavy duty MICC from 7.9mm and above. This test is normally designed for cables over 20mm but the durability and robustness of MICC means it’s the smallest cable ever to achieve a test that involves direct impact, water jet testing and exposure to two hours at temperatures in excess of 800˚C all on one single cable sample.

You have spoken a lot about the need for enhanced testing. Why do you believe this is necessary?

As we all know, fire is a dynamic force that moves, expands, and changes the shape, size, and properties of all it encounters.

Currently, only fire-resistant cables that are greater in diameter than 20mm must undergo testing for direct impacts to reflect falling debris and water jet testing on a single test sample. Why this is set at 20mm no expert in the field can answer, all we know is it rules out almost 90% of the entire MICC range as their diameters are under 20mm. However, with guidance from LPCB WMC achieved this approval (BS8519 CAT3) for their range of Heavy Duty Cables measuring just 7.9mm in diameter.

For fire resistant cables under 20mm, different stages of each test are carried out on different samples of cable, not continuously on the same sample. As the call for mandatory sprinkler systems in taller buildings gathers momentum, it becomes even more concerning that smaller fire-resistant cables, especially those under 20mm, may not survive fire, water, and direct impact - a true fire scenario.

This has resulted in too many cables being classed as fire resistant but that would not be adequate in the event of a fire, as the tests do not represent real-world conditions. In an era of greater accountability, there should be no compromise. We can no longer aim for minimum compliance to get the job done. A higher classification of cables would help people in positions of responsibility identify fire resistant cables which can survive, rather than simply resist fire.

Failure to recognise the need for a true fire scenario test is extremely real. In 2018, a survey of fire-resistant cables conducted in Hong Kong found that 75% of 12 fire Resistance cables removed from public sites, all of which were used in safety-critical systems, failed the very tests to which they were certified. One sample failed the basic fire test of BS 6387 after just 22 minutes. This demonstrates the inconsistency in the standards performance to measure true or real fire condition performance.1

It is for that reason that we have been calling for more stringent testing standards with the introduction of a higher classification of fire-survival cable, for those which can continue to power critical circuits in the event of a fire and withstand the rigours of safety systems such as falling debris, collapsing walls, fire hoses or even activation of high-pressure sprinklers and smoke extraction.

It’s hard to ignore the push towards sustainability across the built environment. How is Wrexham Mineral Cables addressing this?

As a responsible manufacturer, we understand the role we can play in reducing the impacts our products have on the world around us. We have seen increasing demand across the construction sector for products that offer reduced, or are completely free of, plastic components.

Although recycling efforts are changing, cables that contain artificial fire retardants are still extremely difficult to recycle, potentially resulting in tens of thousands of tons of unrecyclable plastic being sent to landfill.

With MICC Cables we don’t need any plastics or polymer covers to aid fire protection. We offer an OPTIONAL LSZH outer cover but this is mainly for cosmetic purposes only. We offer a bare MICC that is completely plastic free, operates continuously up to 250˚C, and for over 3 hours at 950˚C. Our bare cable option consists of just two inorganic materials, where the copper element is 100% recyclable. The result is a totally inorganic and silicone free cable that maintains integrity in extreme fire conditions, whilst offering an environmentally friendly solution.

By comparison, ANY other cables on the market require plastics or polymers to protect the conductors. Whether this be a standard electric power cable in to a property or a Fire Resistant cable to meet BS8519CAT3. As an example, A standard SWA 4 core 4mm cable can contain around 270g of plastic per 1 metre length – the equivalent of 54 plastic bags being sent to landfill.

MICC cable is also a non-ageing product and does not use any plastics to aid its fire performance.

Wrexham Mineral Cables is the world’s leading manufacturer of Mineral Insulated Copper Cable. Based in the UK, the company serves a global customer base in diverse sectors such as oil and gas, Petro-chemical, construction, power generation and distribution, and defence, as well as also rail and transportation infrastructure.

To enquire about Mineral Insulated Copper Cables, please email us on [email protected] or visit our contact page